ACCURACY FABRICATES TRUST

Fabrication

Once the design process is complete, it’s time to fabricate and build. Our manufacturing process gives us the flexibility to create the custom products our clients have come to expect. With great attention to quality, we employ a talented group of Welders, CNC Machinist and Mechanical Assembly Technicians whose skill and experience allows Hokuto USA to complete design builds of more complexity.Hokuto USA complete builds are installed and tested here in our facility prior to delivery. Our Mechanical Technicians, test and modify these systems per customer request to fabricate the desired results. CAPABILITIES

Mig/Tig Welding - MIG and TIG welding both use an electric arc to create the weld. The difference between the two is the way the arc is used. MIG (metal inert gas) welding uses a feed wire that constantly moves through the gun to create the spark, then melts to form the weld. TIG (tungsten inert gas) welding uses long rods to fuse two metals directly together. Our professionals provide high precision for a wide range of applications.

Mastercam Program - Mastercam program has top software strategies to exceed your expectations.

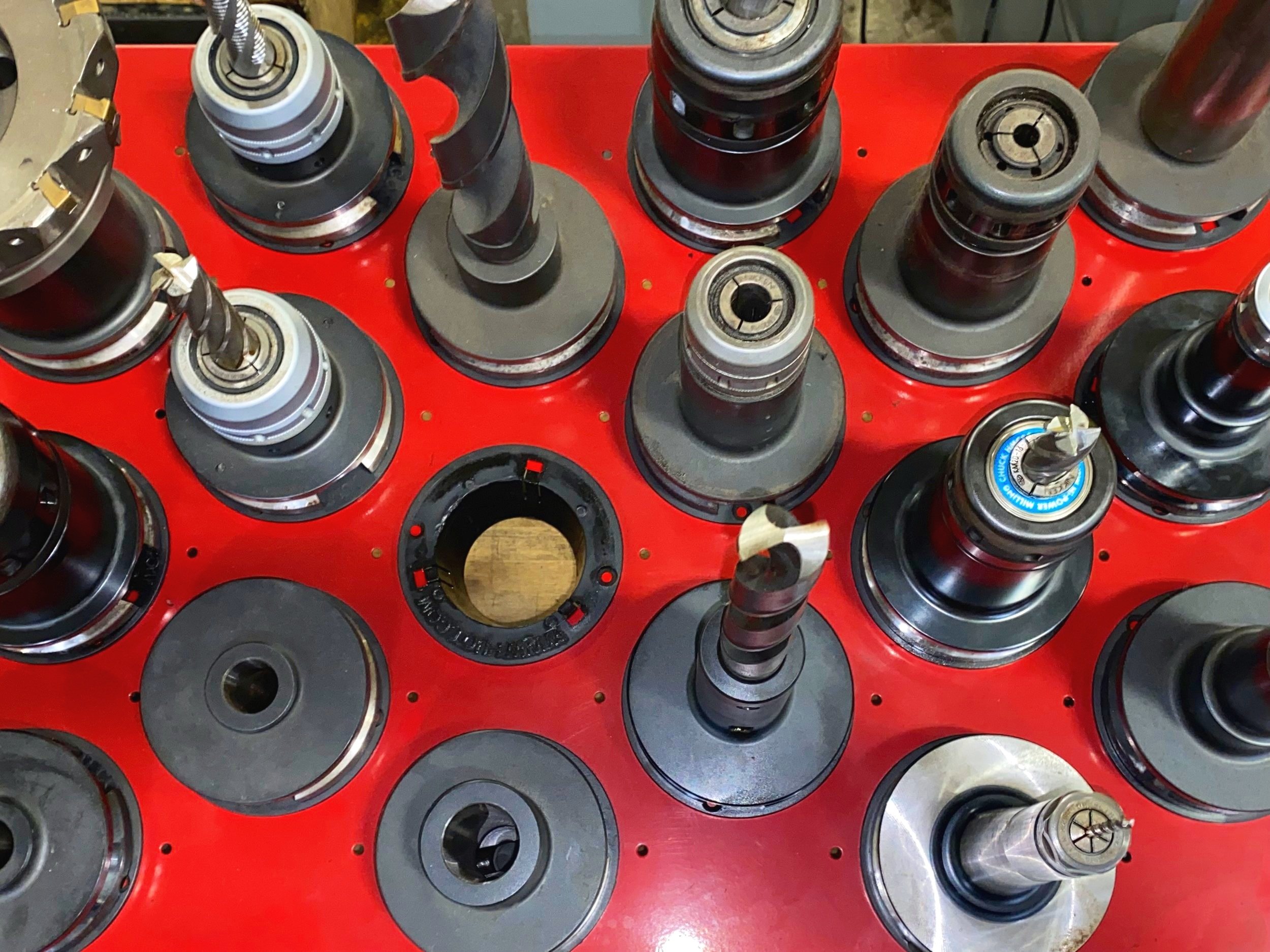

CNC Machinery - CNC milling delivers faster and more accurate qualities in various market; Automotive, Aerospace, Electronics, Technology, Transportation and more.

Horizontal CNC Milling Machinery - Horizontal CNC milling machine is functional for heavy duties such as slots, grooves, pocketing or facing on multiple sides.

Vertical CNC Machine - Vertical CNC milling is excel at detail works as plunge cuts or drilling specific parts operating well with long and thin materials.

5 Axis Machine - The advantage of 5-axis simultaneous machining is the capability to create complex parts in a single operation.

CNC Lathe Machine - Lathe machine has clamps and a rotate function for milling, boring, drilling or tapping. This makes complex works. possible.

and more.

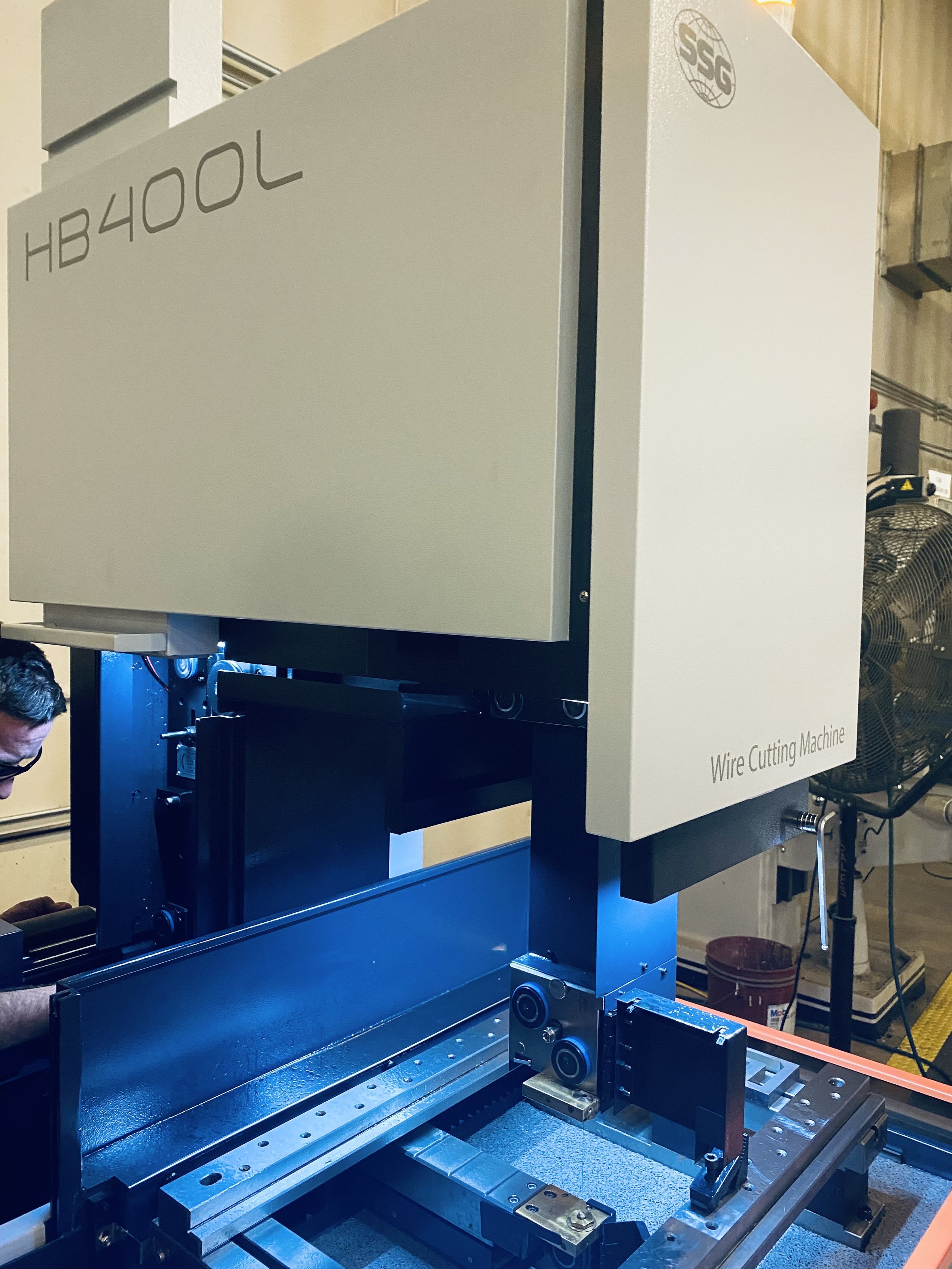

EDM - Electrical Discharge Machining (aka spark machining, spark eroding, die sinking, wire burning or wire erosion) is a metal fabrication method cutting by electrical discharges.

Wire Cutting Machine - Wire cut EDM machine cuts with a 5 different dimensional axis which applies high qualities performance.

3D Printer

Carbon Fiber Composite 3D Printer - Carbon fiber composite 3D printer has a capability of printing continuous fiber reinforced parts, which can be as strong as machined aluminum.

Vertical Machining

Horizontal Machining

3D Printer