MANUFACTURE CREATES THE FUTURE

-

Design

Our design team outfits you with the most beneficial process.

-

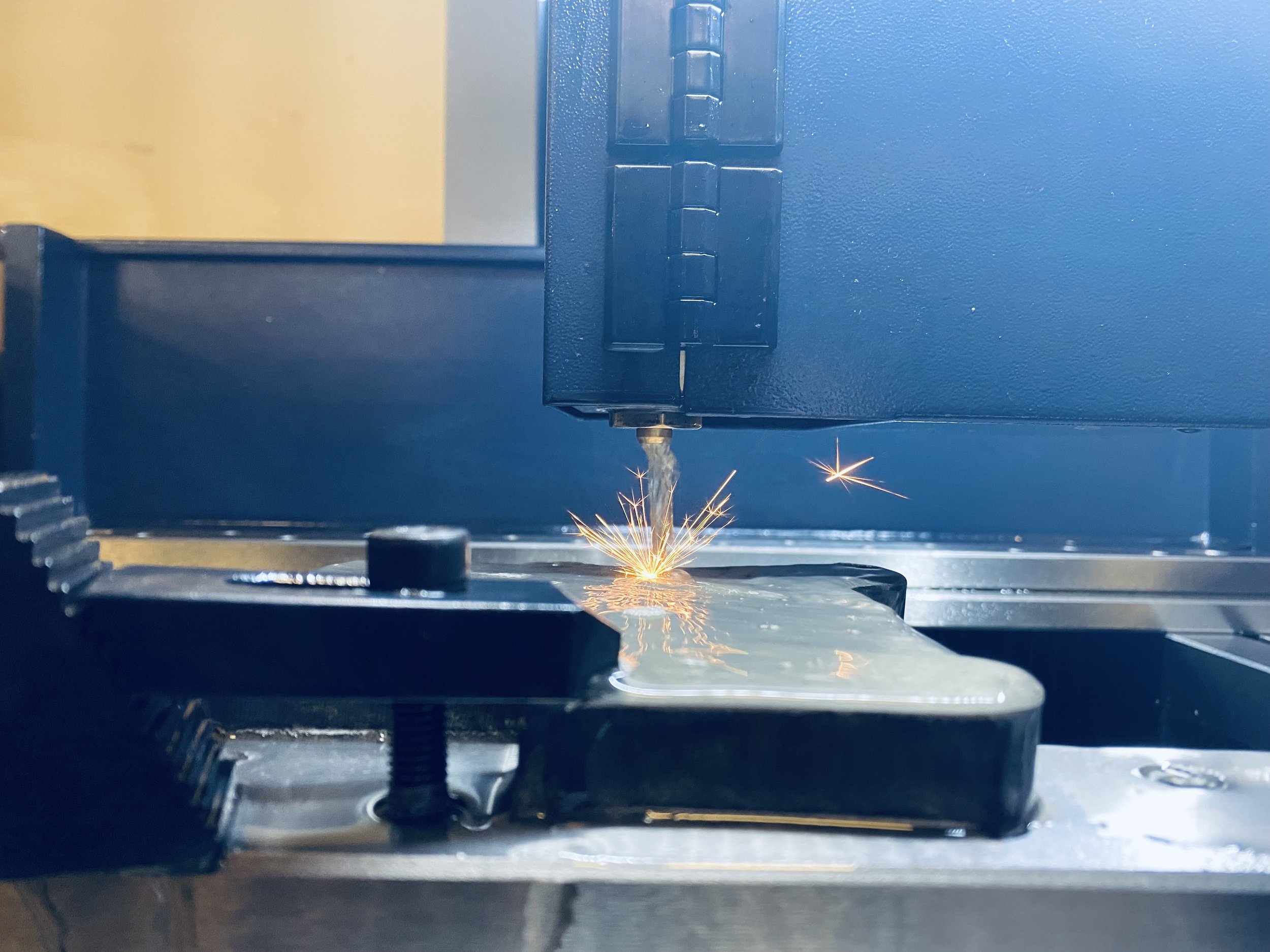

Fabrication

Our fabrication team fabricates and machines delivering high quality parts for best systems

-

Assembly

Our mechanical team builds systems per customer request for desired results.

-

Quality

Our quality team is committed to offering the best industrial automated systems.

-

Robotic

Our robot team has experts to handle all your robotic programming needs.

-

Electric

Our electrical team has the experience and technique to exceed your company.